Linear motion technology finds application in several devices, some of which we use in our daily life. Such devices are generally used for industrial processes, and they work with the help of linear actuators.

These actuators are utilized in a wide range of industries. They offer numerous benefits when compared to the other available types of actuators. A linear motion system uses a power component such as an actuator or a motor.

Unlike the traditional motors that provide a rotational motion, motors operating on linear motion technology have linear forward and backward motion. If you are also looking to buy linear motion products, visit this site. This article will discuss some basic things that you must know about Linear Motion Technology.

Can Work Without Any Mechanical Contact

Linear motor technology is used to convert electrical energy to linear motion. Linear motors offer a host of benefits and are more effective as compared to the other similar available devices.

These motors are capable of working without any mechanical contact. The transmission requires some force, which is generated in the air gap of the rotor. The best part is that no friction is generated during the process, and thus there is no loss of energy.

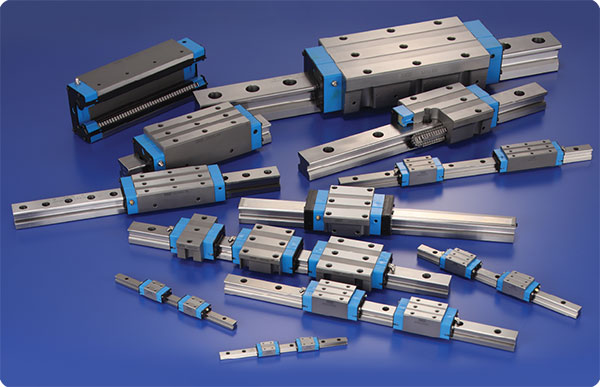

Simple Structure

Most linear motors have a very simple structure, and thus you can easily make a linear motor by using only a few components. These motors are quite reliable, and you will not have to worry about the breakdown of any of the parts. Moreover, the itinerary of operations or its application is not limited.

Wide Speed Range

The speed range of motors employing LMT is quite extensive. The LMT motor actuator can easily move from just a few micrometers to a few meters in a single second. High speeds achieved by the electric actuator are one of the major advantages of LMT devices.

Smooth Motion

The value of acceleration produced in linear actuators is remarkable. Since it has negligible mechanical connections, the motion produced is smooth. Moreover, since there is no friction, no sound is produced during the operation. A feedback device effortlessly reaches the sub-micron level.

Easy Maintenance

It is a cost-efficient option that is quite simple to use and easy to maintain. That being said, minimum to no maintenance is required to keep the device operating.

Finds Application In Numerous Fields

Lately, a lot of devices work on linear motion technology. From moderately simple to complex coordination systems, linear motion technology finds application in all. Linear Motors consist of a moving “reaction plate,” and it follows a traveling wave of magnetic flux produced by stationary coils.

These motors are generally flat and are the unwrapped versions of the traditional motors. Numerous machines employ linear motion, and you will find linear motion devices in almost every sector. Some of them are mentioned as follows:

- Medical: In the medical sector, linear motion is used in technical devices, such as X-ray machines, operation theatre beds, CT scanners, MRIs, and on the dentist’s chairs as well.

- Aerospace: In the aerospace industry, linear motion technology is used in several devices such as the aircraft seats, the equipment used at the airport, and the extraction of slide-out components on the aircraft.

- Furnitures: Linear motion technology is required in retail stores, hotels, yachts, theatres, and museums. You can also find devices using LMT at our home, in the kitchen worktops, and on display cases or sliding doors. The LMT rails are generally used as safety barriers for the elevators.

- Industrial and Packaging: LMT is used in devices that are used for packaging and palletizing purposes. They are also used in devices that serve pick and place operations, positioning the loads, automated warehouses, and filling operations. Workstations that are used for painting machines, cutting machines, etc., also use LMT.

3 Types of Linear Motion

Three major types of linear motion include pneumatic, hydraulic and electric. All the three usually do the same job, and it is just that their way of attaining straight line motion is different.

Moreover, the different applications have different advantages and drawbacks as well. Let us know about each type so that you make a better decision regarding which one you should use for your application.

1. Hydraulics

These actuators are quite expensive, and they require certain peripheral equipment for their operation that adds to its cost. Also, the cost of the maintenance is quite high. However, they are quite reliable and are fast and accurate. Car Jack is a common example of this type of actuator.

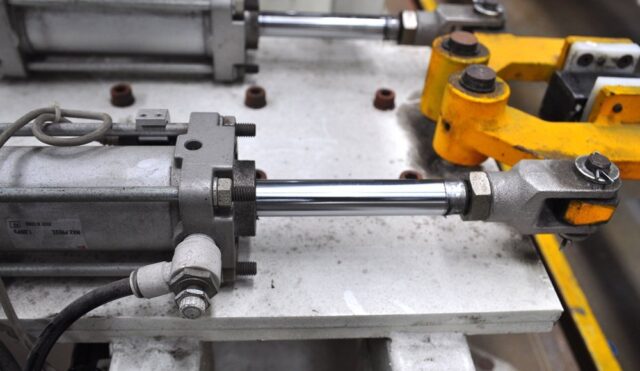

2. Pneumatic

These actuators employ a piston present that is placed inside a cylinder. A manual pump moves the piston up and down. With an increase in pressure, the cylinder moves in the direction of the piston’s axis, thereby producing a straight line motion.

It goes back to its initial position either with the help of a spring or due to the pressure exerted by a fluid present on the opposite side of the piston.

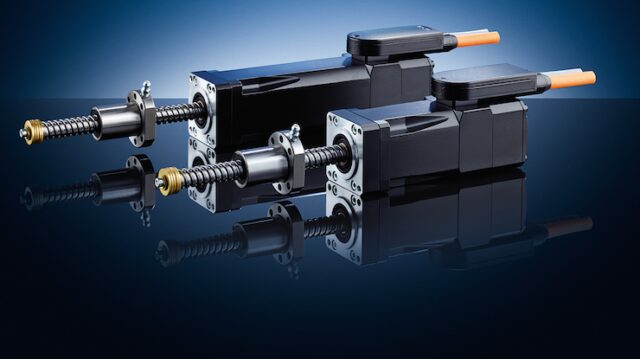

3. Electric Linear Actuators

These actuators are also known as electric cylinders or electric lift cylinders. They convert the rotary force of the motor and into linear motion. By rotating the screw of the actuator through the motor, the nut tends to move in a line and goes up and down, thus creating a push and pull effect on the load.

All these actuators serve different purposes; however, you can use one actuator to serve the other actuator’s purpose due to technological advancement. However, you need to make specific changes to achieve that.

Final Word

We hope you are aware of what LMT is and how it works. LMT devices are used in numerous varieties, including heavy-duty items, devices that need high-speed, and several other types of devices.

Every actuator prototype has unique capabilities and characteristics.

There are three different types of actuators and each have its own set of advantages and disadvantages, and thus, you must weigh them before buying an actuator for your project.