The only way an industry can survive is by constant innovations and trends that shape it and propel it to higher standards. One industry where innovations and trends play a huge role in the injection molding industry.

But what are the latest happenings in the industry that make them so important for the overall success? Well, to answer that question we will have to go more in-depth. And if you have the time for it, then this is the article for you.

Without further ado, let’s start.

1. Engineers Play An Important Role in Design

Engineers and design are two things that we probably don’t hear that often, especially in injection molding. But as the years go by, the engineering standards have been at a level that no one would have anticipated.

This means that an engineer has to be involved in the design and making of new parts, machines, and everything else that make up the core of the industry. Why we do that? We do that because an engineer knows the ins and outs of each part and machine.

Thus, an engineer understands the needs of each product to be better in every aspect.

2. The New “Micro” Injection Molding

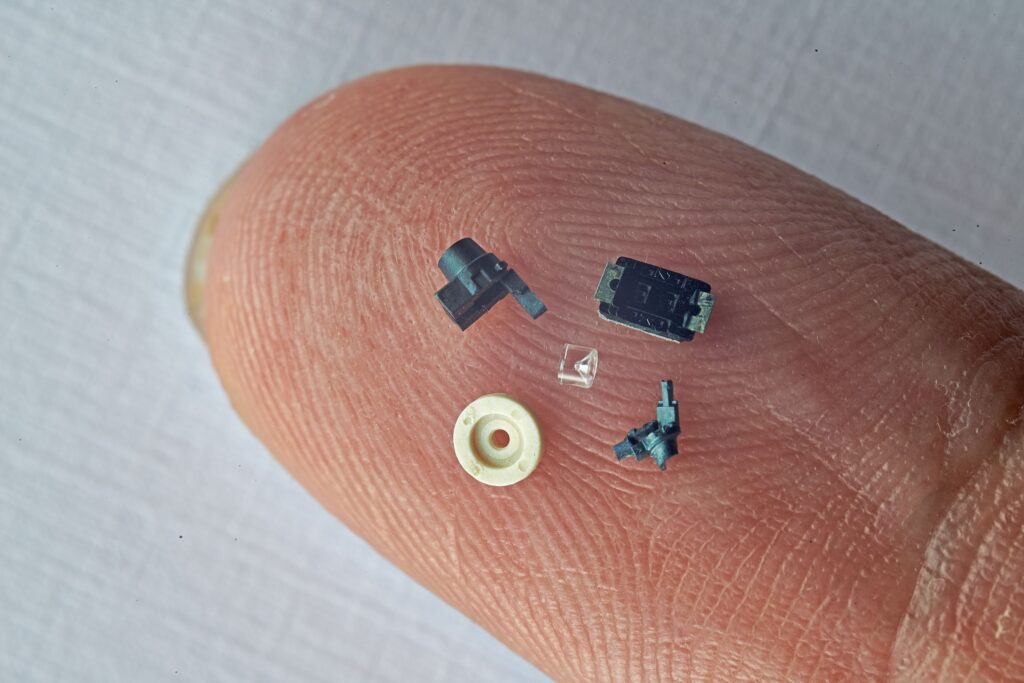

Whenever we talk about micro injection molding things get confusing. That’s because the word “micro” has become a sort of buzz word in the industry. But this is the literal definition of the meaning. Micro injection molding involves the molding of parts on a microscopic scale.

Imagine what you can do with such a practice? But if this is still unclear to you, then fear not as we will explain it a bit deeper.

The need for smaller devices and parts to be used in such devices has become a key part of the industry. This is how the practice of micro injection molding came to be.

With this practice, we can design, develop, and manufacture on a microscopic level. This mostly suits the medical industry, but there are others that also benefit from such a practice. To put it simply, any industry that requires injection molding on a microscopic level can benefit from it.

It is a technological advancement that has changed the way the industry operates, and for the better.

3. The Impact of Eco-Materials

Whatever the industry, being environmentally safe has been a priority. And such is the case with injection molding. A lot of manufacturers have put out contracts for the creation of materials and parts that are environmentally safe.

This has, in turn, caused a massive shift in the type of materials being used for the making of components and parts. Some of the materials that have had to suffer are plastic and various others that produce toxic waste.

In essence, we’re seeing a massive shift towards eco-materials and thus preserving the environment. While the injection molding industry isn’t really a huge polluter, the shift has caused a massive change.

4. Sustainability and Quality

The only way an industry can sustain itself, in the long run, is by focusing on quality and longevity or sustainability. While this might seem like an obvious thing, it is far from it.

Many neglect the need to focus on quality products, and instead only focus on profits. But it is these trends that have put the injection molding industry aside as one of the most sustainable.

Truthfully speaking, we have a lot of responsibility as manufacturers in creating products that will last longer. But more so than that, we have to make sure that the equipment is capable of multi-year functioning.

And as a subsequent quality and sustainability, we are seeing an increase in profits in the long run.

A lot of injections molding companies, such as qmolding, are equipping themselves with the latest technologies and innovations that promote quality and sustainability. And these are the sort of companies you should be doing business with.

5. Automation

Automation is probably the innovation that most of you would have probably guessed. And this is the sort of topic that gets the most attention whenever we talk about technological advancements and changes.

The impact automation has had on most industries is so big that we don’t really talk about it because it has become the norm. Frankly speaking, automation has existed for quite some time now.

This is actually why a lot of experts disregard automation as an innovation, simply because of how long it has existed. But that doesn’t mean we can underestimate the importance of automation.

Through automation in injection molding, we are making it possible to create better products at a faster rate. What’s more important is that we also make it possible to cut back on costs and employ a system that replaces humans as workers.

While many see this as a negative thing, it is actually a positive because we can direct people to other fields.

6. Rethinking the Supply Chain

Automation has completely transformed the injection molding industry. But that has also caused a domino effect on the supply chain.

And it is the security and safety of the supply chain that has proven to be invaluable. Luckily, we no longer have to worry about contracts and agreements and instead rely on automation to do the trick. Nowadays, fulfilling orders, scheduling departures, and deliveries, and even sending them to offshore locations is made easy through automation.

This is why we have specialized software for it. Nearly every injection molding company uses such software, thus reinforcing the “invaluable” statement.

And it is this radical change of the way we conduct the supply change that has had the biggest impact. We longer have to do all that the hard way, and instead rely on software.

Conclusion

While some more innovations and trends can be named and explained, these are the ones that have radically changed the industry for the better.

Staying up to date with the latest advancements it’s important if you want to promote quality with your products. And by understanding the innovations, you can also know which company provides a quality service.