Laser cutting is something many people have heard of, but unless you work in design, manufacturing or engineering, it is not always clear what it actually involves or why it might be useful.

A laser cutting service offers precise, computer-controlled cutting of materials using high-powered laser beams. From intricate metal parts to custom signs and prototypes, this service is used in a wide range of industries and projects. Its combination of speed, accuracy and flexibility makes it one of the most efficient ways to turn digital designs into physical forms.

Here is a closer look at what it is, how it works and when you might need it.

How Laser Cutting Works

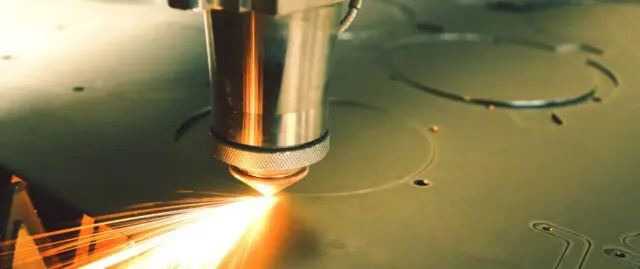

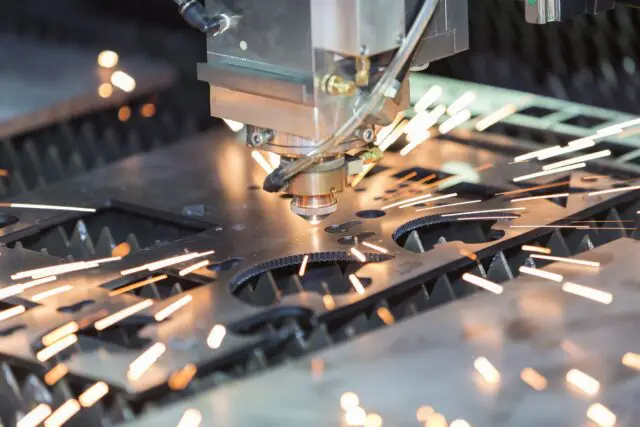

At its core, laser cutting uses a focused laser beam to cut or engrave material. The process is usually controlled by a computer (often using CAD files) which allows for very precise and repeatable results. This makes it ideal for applications where tolerance and detail are essential.

Depending on the material and laser type, the beam can melt, burn or vaporise the surface, leaving a clean and accurate cut edge. In many cases, assist gases such as oxygen, nitrogen or air are used to improve edge quality and prevent burning or discoloration.

It works on a range of materials, including:

- Metals (steel, aluminium, copper)

- Plastics (acrylic, polycarbonate)

- Wood

- Paper and card

- Fabric and leather

Each material type requires specific power levels and speed settings. A professional service will select those settings based on the job’s detail, thickness and finish requirements.

Common Uses for Laser Cutting

Laser cutting is incredibly versatile, which is why it is used in so many different settings. Some common applications include:

- Custom parts for machinery or vehicles

- Architectural models and prototypes

- Signage and lettering

- Jewellery and fashion accessories

- Decorative panels and interior features

- Packaging and product design

It is often chosen for its ability to create detailed shapes that would be difficult or time-consuming with traditional tools. Engraved patterns, internal cut-outs, perforations and curved lines are all easy to achieve. Artists, engineers, educators and entrepreneurs use laser cutting to test ideas and create professional-level results on almost any flat material.

Even in industries like automotive or aerospace, laser cutting plays a role in creating lightweight parts or components with precise tolerances. In creative fields, it allows small studios to fabricate unique pieces without needing a large workshop or expensive tools.

Benefits of Using a Laser Cutting Service

Hiring a professional laser cutting service brings a few key benefits:

- Precision: Fine details and complex patterns can be cut with a high degree of accuracy.

- Consistency: Once set up, the machine can cut multiple identical items without variation.

- Clean Edges: Laser cuts are typically very smooth, often requiring little or no finishing.

- Material Efficiency: Because of the narrow cutting width, less material is wasted compared to other methods.

Laser cutting also reduces the need for manual adjustments or rework. Files can be quickly modified and re-sent to the machine, making changes easy without restarting the entire process. For time-sensitive jobs, that speed can make a real difference.

Another benefit is reduced mechanical stress. Unlike traditional cutting tools that apply force, lasers cut without touching the material, which helps avoid warping or distortion on delicate surfaces.

It is also a flexible option for both one-off projects and large production runs. Whether it is a single prototype or thousands of identical items, the same level of detail and quality can be maintained.

When Might You Need It?

You might consider using a laser cutting service if:

- You are working on a custom design and need precise cuts

- You need to prototype something quickly

- You are producing parts in small or medium quantities

- You want to create something decorative or artistic out of sheet material

It can also be helpful if you need to outsource a process you cannot perform in-house. Many shops lack the tools or time to do complex cutting manually. A laser cutting provider can fill that gap affordably.

Even hobbyists and small businesses can make use of laser cutting today. Many services cater to short runs and individual pieces, not just mass production. Some even allow you to upload a file, choose a material and receive finished parts within days.

Whether you are crafting a sign, preparing a school project or developing a prototype, access to a reliable laser cutting service expands your creative and technical capabilities.

In Summary

A laser cutting service can be a smart choice when accuracy, detail and consistency matter. Whether you’re creating a piece of signage, developing a new product, or just exploring ideas, it offers a reliable way to turn digital designs into physical objects.

As the technology becomes more accessible, it’s opening up creative possibilities far beyond the factory floor.