Today, we try to keep the causes of industrial wastewater under control. We do it through appropriate primary treatment measures. These measures ensure that substances that spread harmful fumes, unpleasant odors, and attack drainage devices – do not enter the public sewer. Today, grease traps find their wide application – from households to industrial plants. But how do you maintain them if you already have them? Here are 5 preventive maintenance tips for your grease traps.

What Are Grease Traps?

Grease traps or grease separators are devices that serve to separate grease of animal and vegetable origin, from wastewater from kitchens, canteens, restaurants, dairies, slaughterhouses – and plants for processing meat and fish. They have wide applications everywhere where greasy food is processed or prepared – and dishes are washed. Grease separators prevent the grease from sticking to the sewer pipes and clogging the drains. This way, they also prevent environmental pollution.

Application And Standards Of Producing Grease Separators

When we talk about the application of such separators, we have already mentioned that they are used almost everywhere – from households to factory plants. Certainly, the size and capacity of these devices differ in these cases. These separators, in terms of construction and functioning – are made by following the relevant standards.

Depending on the need, the size of the grease separator required for a specific purpose can be selected – and thus offer customers the appropriate solution. What is particularly practical is that these traps are made to be light, relatively small in size, long-lasting – and easy to install and for maintaining. Therefore, they are suitable for use in restaurants, kitchens – but some separators are also used in food and meat industry plants, for both – smaller and extremely large capacities.

Additional Requirements

Grease separators should be installed in fat-containing wastewater plants – to make sure the retention of grease and oils of organic origin from contaminated water. As professionals from www.greasetrapsanfrancisco.com claim – this is used for meat processing plants, restaurants, hotels, etc. Behind each grease separator installed below the deceleration level (usually the below the ground level) – there must be a free-standing pumping station with two pumps or a pumping shaft with two pumps. Due to a large number of specific requirements in the field – you can find a wide range of products on the market, such as grease traps, pumping stations – but also ready-made pumping shafts for installation in the ground or free-standing installation.

Learning About Use And Maintenance

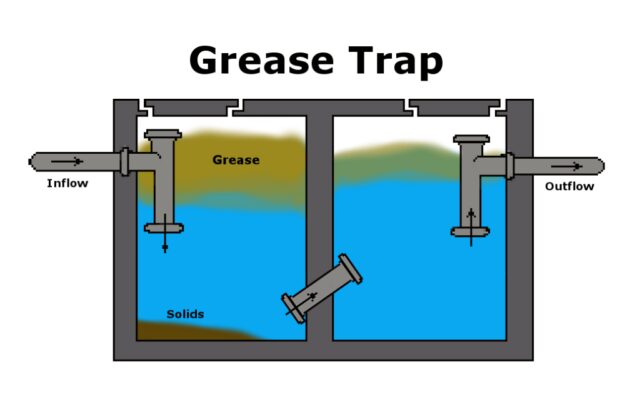

A grease trap is actually a tank in which substances of less specific gravity than the specific gravity of water are separated – by floating on the surface. The reduced fluid velocity allows sedimentation of a part of the solid matter – that settles to the bottom of the tank. As the temperature has a significant effect on the process – it becomes 100% effective when the temperature is not much above the melting point of the grease, approximately 20 C.

Substances separated by floating on the surface form a surface crust – while heavier substances settle at the bottom of the separator forming sludge. It is recommended to periodically remove the accumulated material by special technicians – in order not to reduce the effective volume, retention time, and effectiveness of the grease trap. Uncontrolled sludge deposition can lead to septic conditions and bad smell, especially during summer.

Preventative Maintenance Tips For Your Grease Traps

The fat trap is an almost inevitable tool used in kitchens, restaurants, fish, and meat processing plants, etc. By making it easier for us to dispose of waste, grease traps have become indispensable in many industries, and even in households, even though they have smaller capacities there. Of course, for grease traps to work well, you need to maintain them the right way. Here are some preventative tips for maintaining grease traps.

1. Check out if the installation is properly fixed

Proper installation of grease separators is rule No. 1 you need to follow. This installation primarily involves the proper connection of the entire system. If you don’t have a septic tank for wastewater disposal – this means that you must transport waste materials to the intended disposal site. Therefore, the company that installs grease separators must also install garbage disposal tanks after grease traps. If the opposite happens, and wastewater tanks are installed in front of grease traps – they can be filled with sludge and waste, which will jeopardize their function. Of course, you must check in advance whether the size of your grease trap and its capacity suits your needs.

2. See if there’s grease in your trap

When you install the grease separator, you start using it. After a while, usually a couple of days – you should check to see if fat is accumulating in your trap. If it is not there, it is an alarm signal that indicates that your grease trap is not working adequately, that is, that it’s not well installed. It is therefore advisable to contact professionals immediately who will solve this problem or reinstall the trap. It is very important to check the correctness of the installation from the very beginning so that you do not have major problems later.

3. Try with installing strainers into your sink

When it comes to grease, in addition to grease traps, it is recommended to install strainers in sinks. They should be installed in sinks, drains, and grills in dishes, but also dishwashers. This way, you will prevent the discharge of dirt and grease into the drain – and prevent possible clogging of the pipes, which would prevent the normal functioning of the drainage system. When such situations occur, they can pose a major problem and do more serious or permanent damage.

4. Remove food debris

Of course, this is also a matter of lifestyle and living culture, but it’s also practical help in a situation when you have contact with leftover greasy foods. Avoiding spilling grease into the sink drain is something that should be normal. Of course, you can’t completely avoid spilling greasy and dirty water – but at least you can remove larger residues of greasy food to prevent congestion and deposition of large amounts of grease on your trap. This will maintain its longevity.

5. Regular professional maintenance

To properly maintain the trap, it is very important to frequently pump out the grease which is accumulated and deposited in the container. Therefore, you must call professional technicians for this purpose – who will deal with the regular maintenance of grease traps. Professionals will help you in practice but will also give you several useful tips on how to prevent problems, how often to clean grease traps – and also what you can do yourself to make your grease traps work optimally.