We live in age of reality of customizing things, some call it the Third Industrial Revolution. 3D printing is the new hot thing. This was just a Sci-Fi idea 20 years ago when actors in Star Trek used similar device called Replicator, which was something magical that could create objects out of air by printing nylon, metal, plastic and may other materials. 3D printing is today slowly starting to turn into addiction for many manufactuters that are printing all kinds of things from legal guns, engine parts, car prototypes, or even houses and human organs. First signs of 3D printing technology was back in 1986 year, but it didn’t got enough attention until early 90’s. In that era 3D printing was not very popular technology in world of manufacturing and architecture. The process of printing is basically creating 3D models of any objects you have in your digital form. It’s done by building 3D objects creating layer by layer and shaping it until object is finished.

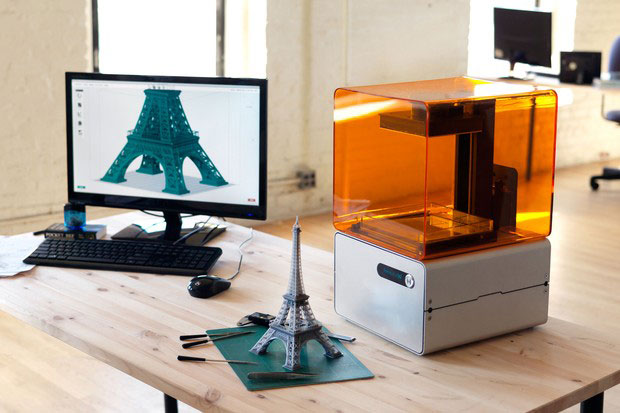

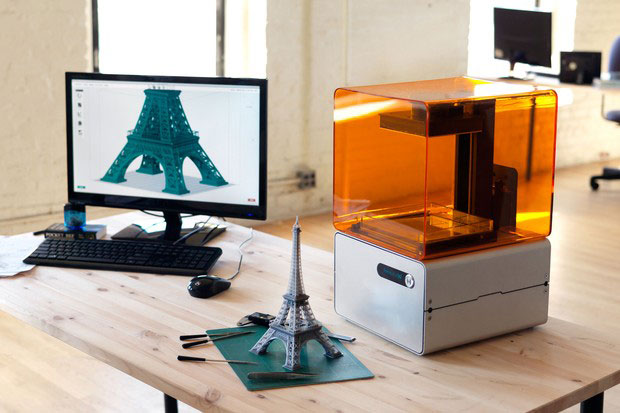

If you have skills in working with design softwares like CAD, you can create your own 3D images, or if not, you can download them online. One of most important aspects of 3D printing is possibility to print parts for medical industry. So doctors and surgeons can create parts for patients or create prototypes to see how it would fit to the body. If you need some part for your home device you will simply print it. 3D printers are still very expensive for home users but you can print something at local store that has them. If if easier to understand, picture a cake, with muli players, and then baker is putting layer by layer on top of each other until full cake is created. 3D printing is similar to this but super precise.

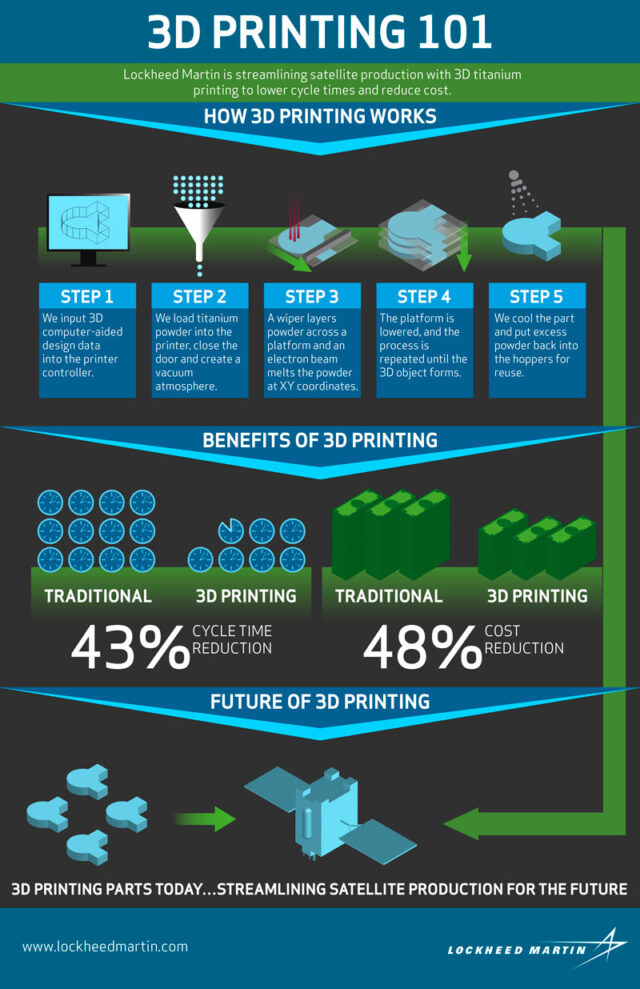

So how 3D printing works in details?

Well, everything in 3D printing begins with digital files. 3D printer needs instructions so it can know how and what to print. The files are usually in CAD format and created with 3D software. You can either scan 3D model and upload it in software or create everything from scratch. When the file is uploaded, application dissects designed file into thousands of layers and each of these layers are being printed on top of another until the design is fully completed. There’s a number of free programs that you can use and learn on them.

One of the thing that fascinated me is 3D printing of yourself of other members of your family. There’s a company called Twinkind where you can go and they take many pics of you from various angles along with scanning of your entire body, then they print your mini 3D version that looks like a figure. It’s really incredible and I wish I could try this technology on myself. If you are located in Germany and living in Hamburg or Berlin, make sure to stop by and try it for yourself.

Technology of 3D printing will impact every aspect of our lives in the future, be it from medical, technological, business , architecture or car industry. Imagine going into space on the Moon or Mars and printing entire houses and any parts astronauts needs. It also helps in saving great deal of money, even for companies because they can create many parts for single product and see if all fits together, but while they’re doing it they are using cheaper materials for printing so they know in the end if its worth to build the real one. 3D printing allows us to experiment with designs and ideas in many ways. This industry is expected to constantly grow. I can’t wait to buy one 3D printer for myself first chance when it’s going to be affordable.